Get Professional Help

Agitators for Pharmaceutical Industry

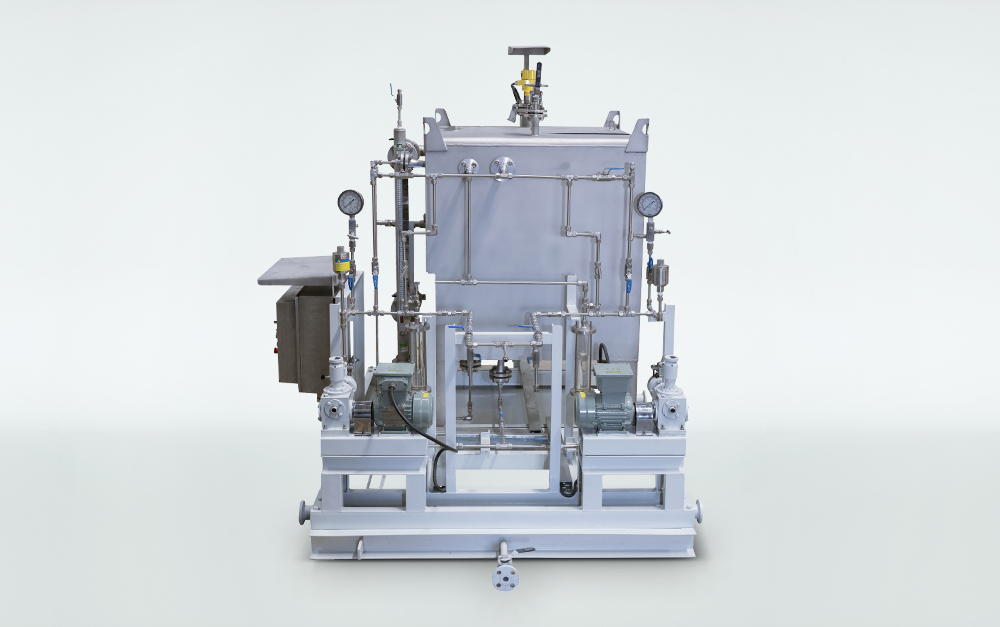

STEADO specializes in designing and manufacturing high-performance agitators tailored to meet the critical demands of the pharmaceutical industry. Our solutions are engineered for precision, reliability, and contamination-free mixing, making them ideal for processes where product integrity and safety are paramount.

From small-scale laboratory applications to large-scale production environments, STEADO agitators ensure:

- Consistent and repeatable mixing results

- Full compliance with cGMP and regulatory standards

- Sterile and hygienic operation with CIP/SIP compatibility

With STEADO, you can trust in agitation technology that enhances process control, minimizes risk, and upholds the purity your pharmaceutical applications require.

Understanding Agitation in the Pharmaceutical Industry

Agitation is a vital part of pharmaceutical manufacturing, impacting product quality, stability, and efficacy. STEADO’s agitation solutions are engineered to address the complexities of modern pharmaceutical processes, including:

-

Blending:

Achieving uniform mixing of active ingredients and excipients. -

Suspension:

Maintaining consistent dispersion of insoluble particles in liquid formulations. -

Emulsification:

Forming and stabilizing emulsions for enhanced drug delivery. -

Dissolution:

Improving solubility and bioavailability of active pharmaceutical ingredients (APIs).

STEADO’s Pharmaceutical Agitator Range

Our agitators are tailored for precision, sterility, and compliance — designed specifically for the pharmaceutical sector:

-

Anchor Agitators

For high-volume blending with efficient circulation and minimal product buildup. -

Propeller Agitators

Fast, high-speed mixing for low to moderate viscosity liquids. -

Turbine Agitators

Delivering high shear mixing for thorough dispersion and challenging formulations. -

Helical Ribbon & Parabolic Agitators

Ideal for high-viscosity products; ensures uniform mixing and minimizes dead zones.

Key Features & Benefits

-

Hygienic Design:

Mirror-polished surfaces and crevice-free construction for easy CIP/SIP cleaning. -

Pharma-Grade Materials:

SS316L, Hastelloy, and other corrosion-resistant alloys ensure biocompatibility and longevity. -

Advanced Sealing Systems:

Leak-proof mechanical seals protect product purity. -

Energy-Efficient Operations:

Variable speed drives for process optimization and reduced energy use. -

Automation-Ready:

Seamless integration with SCADA/DCS systems for real-time control. -

Precision Mixing:

Engineered impellers ensure consistent and homogeneous results. -

Custom Configurations:

Designed for your tank geometry, viscosity, and shear sensitivity. -

Full Compliance:

Designed in accordance with FDA, GMP, and other global pharmaceutical standards. -

Scale-Up Ready:

Consistent performance from lab-scale to commercial production.

Why Choose STEADO for Pharmaceutical Agitation?

-

Specialized Expertise:

Decades of experience in pharmaceutical-grade mixing technology. -

Global Standards Compliance:

FDA, GMP, and international norms met with confidence. -

Tailored Engineering:

Solutions built around your process goals and constraints. -

Performance You Can Trust:

Long-lasting reliability in sterile and regulated environments.

STEADO agitators are trusted by leading pharmaceutical manufacturers worldwide. Whether you’re producing sterile injectables, biosimilars, or complex APIs, we deliver robust, contamination-free mixing systems designed for excellence.

Get in touch with our pharmaceutical agitation experts today.

Learn More About Mixing Technology

At STEADO, we offer a wide range of mixer agitators designed to meet the diverse needs of our clients across various industries. Our agitators are engineered with the highest quality materials and built under the guidance of experienced professionals to ensure superior performance and reliability.

Customization for Your Needs

Each mixer agitator is tailored to specific process requirements. We understand that every application is unique, which is why we provide custom-built solutions that align with your operational goals.

Our Commitment to Quality

We pride ourselves on delivering defect-free agitators that are rigorously tested at every stage of manufacturing. STEADO ensures that each product undergoes extensive quality checks to meet the highest standards of performance, durability, and precision.

Agitator Design Expertise

Our team of experts is here to provide insights on the most critical factors for optimizing your agitation process:

-

Tip Speed:

Achieving the ideal impeller tip velocity for efficient mixing. -

Pumping Capacity:

Determining the ideal pumping power for your process. -

Detention Time:

Calculating the residence time needed for optimal processing. -

ChemScale:

Ensuring the right chemical scaling for your material compatibility. -

Velocity Gradient:

Fine-tuning the fluid velocity to optimize shear and mixing. -

Torque:

Balancing motor torque to meet performance requirements. -

Specific Power:

Optimizing energy consumption per unit volume. -

Material of Construction:

Selecting the right materials for your process (stainless steel, Hastelloy, etc.).

STEADO’s Agitator Manufacturing Excellence

We utilize state-of-the-art machinery and qualified procedures to deliver agitators that meet the highest standards:

-

Precision Machining:

Using advanced CNC, VMC, and Lathe Machines for exact tolerances. -

Welding Excellence:

Only using qualified and approved welding procedures to ensure robust, leak-free designs.

Comprehensive Quality Testing

To ensure the highest level of reliability, STEADO conducts a series of rigorous tests on each agitator:

-

Performance Tests:

Run trials to validate operational efficiency. -

Noise & Vibration Testing:

Ensuring smooth and quiet operation. -

Dimensional Accuracy:

Verifying that all parts meet exact specifications. -

Run-Out & Dynamic Balancing:

Ensuring perfect alignment and uniformity. -

Chemical & Mechanical Testing:

Assessing material strength, corrosion resistance, and compatibility. -

Non-Destructive Testing:

Including Ultrasonic Testing (UT), Magnetic Particle Inspection (MPI), Dye Penetrant (DP), and X-Ray for structural integrity. -

Coating & Paint Testing (DFT):

Measuring dry film thickness for surface protection.

Why Choose STEADO for Agitator Solutions?

- Industry-leading Design Expertise

- Custom Solutions Tailored to Your Needs

- High-Quality Manufacturing & Rigorous Testing

- Comprehensive Support for Optimizing Your Processes

Contact our Agitator Design Experts today to find the best solution for your application