Get Professional Help

Agitators for Dairy Industry -

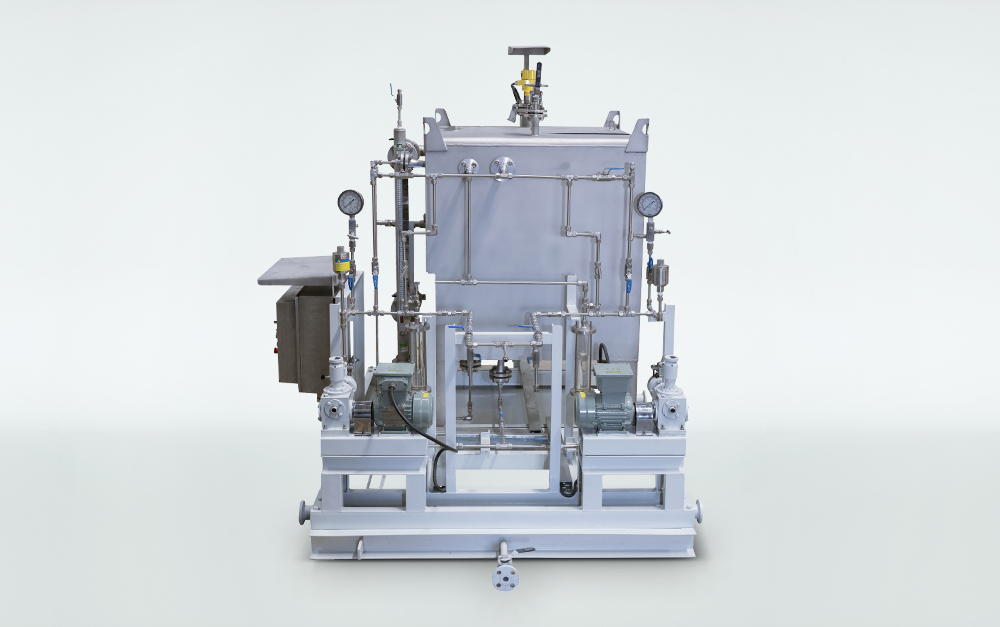

STEADO is a global leader in designing and manufacturing high-performance agitators crafted specifically for the dairy industry. Our cutting-edge solutions are engineered to tackle the unique challenges of dairy processing, ensuring uniform mixing, consistent product quality, and improved operational efficiency.

Built with precision and reliability, STEADO agitators are designed to meet the highest standards of hygiene and product quality in dairy production. From milk to cream and beyond, our agitators are the ideal choice for maintaining product integrity while optimizing your production processes.

Understanding Agitation in the Dairy Industry

Agitation is an essential part of various dairy processes, playing a vital role in maintaining consistency, quality, and efficiency. Key processes benefiting from agitation include:

-

Milk Pasteurization:

Ensures uniform heating and cooling for effective pasteurization. -

Blending:

Achieves precise blending of ingredients to create a homogeneous mix for various dairy products. -

Cheese Production:

Optimizes curdling processes, ensuring consistent curd and whey mixing, which improves yield and consistency for both soft and hard cheeses. -

Fermentation:

Promotes consistent fermentation by ensuring a homogeneous mixture throughout the process. -

Storage:

Prevents product separation and sedimentation, ensuring stability during storage. -

Cream Processing & Butter Churning:

Maintains cream homogeneity and assists in emulsification, crucial for consistent butter quality.

STEADO Dairy Agitator Solutions

STEADO offers an extensive range of agitators, designed specifically to meet the unique demands of different dairy processes:

-

Anchor Agitators:

Perfect for large-scale mixing, these agitators provide efficient circulation and uniform distribution. -

Propeller Agitators:

Ideal for liquids with low to moderate viscosities, offering high-speed agitation for rapid mixing. -

Turbine Agitators:

Designed for intensive applications, providing high shear rates for effective blending and dispersion. -

Helical Ribbon Agitators

Perfect for high-viscosity materials, these agitators ensure thorough mixing and prevent product build-up.

Key Features & Benefits of STEADO Dairy Agitators

-

Customizable Designs:

Specialized impellers optimized for gentle mixing, ensuring thorough blending while preserving the texture and consistency of dairy products. Tailored to handle varying viscosities, from thin milk to thicker substances like yogurt or cream. -

Energy Efficiency:

Designed for minimal energy consumption without compromising on performance, helping dairy facilities lower operational costs while maintaining top-notch mixing quality. -

Precise Control:

Equipped with advanced control systems to manage agitation speed and intensity with precision. -

High-Quality Materials:

Constructed from food-grade stainless steel (SS316L) to ensure hygienic operation and corrosion resistance, meeting international food safety standards and standing up to harsh cleaning regimes like CIP (Clean-In-Place) and SIP (Sterilize-In-Place). -

Hygienic Seals and Bearings:

Features aseptic mechanical seals and hygienic bearings that are easy to clean and maintain, ensuring compliance with stringent dairy sanitation standards.

Agitator Types for Dairy Processes

-

Top-Entry Agitators:

Ideal for large dairy tanks used for milk storage and fermentation, these agitators provide excellent mixing while minimizing shear forces, preserving milk fat integrity. -

Side-Entry Agitators:

Perfect for continuous processes such as cream processing and butter churning, ensuring consistent agitation and reducing the risk of fat separation.

Why Choose STEADO for Dairy Agitation?

-

Industry Expertise:

With decades of experience in dairy processing, STEADO understands the sector's unique challenges and offers tailored solutions to enhance both productivity and product quality. -

Compliance with Industry Standards:

All STEADO dairy agitators meet international food safety and hygiene standards, including 3-A Sanitary Standards and EHEDG (European Hygienic Engineering & Design Group). -

Reliability & Performanc:

STEADO agitators are engineered to provide continuous, reliable operation, reducing downtime and improving the efficiency of dairy production processes.

STEADO Commitment to Dairy Industry Success

At STEADO, we are dedicated to delivering innovative agitation solutions that increase efficiency, quality, and profitability in the dairy industry. We work closely with dairy processors to understand their unique needs, providing customized solutions that cater to their specific production requirements.

By choosing STEADO, you can count on the reliability, performance, and long-term value of our dairy agitators. Reach out to us today to learn how we can help optimize your dairy operations.

Know More About Mixing Technology

STEADO mixer agitators are available in various specifications tailored to meet our customers’ specific needs. We conduct rigorous testing to ensure our agitators are defect-free and of the highest quality. Developed with premium materials under the guidance of skilled professionals, our agitators deliver optimal performance.

Ask Our Agitator Design Experts

- Tip Speed

- Pumping Capacity

- Detention Time

- ChemScale

- Velocity Gradient

- Torque

- Specific Power

- Material of Construction

Agitator Manufacturing Excellence

-

Machining Precision:

Using state-of-the-art CNC, VMC, and lathe machines to ensure accuracy. -

Approved Welding Procedures:

Our welding processes meet strict industry standards, ensuring durability and performance.

Testing by STEADO Quality Specialists

Our rigorous testing processes include:

- Performance Testing

- Run Trial

- Noise & Vibration Testing

- RPM & Current Monitoring

- Dimensional & Run Out Checks

- Dynamic & Static Balancing

- Chemical & Mechanical Testing

- UT, PMI, DP, PT Testing

Final Assembly: Aesthetic Excellence

We care about the aesthetics of our products, ensuring that they are not only functional but also visually appealing and built to the highest standards.