Get Professional Help

Agitators for Water Treatment

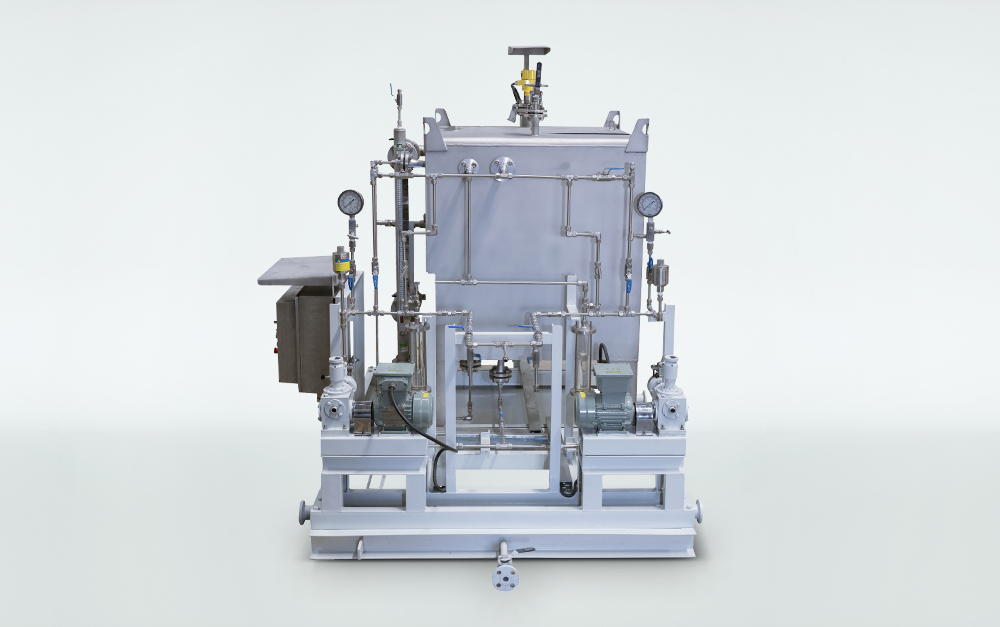

At STEADOEngineering Private Limited, we specialize in designing high-performance agitators for Water Treatment Dosing Tanks. Our agitators are engineered to meet the complex demands of various water treatment processes, including Water Treatment Plants (WTP), Wastewater Treatment Plants (WWTP), Sewage Treatment Plants (STP), Effluent Treatment Plants (ETP), and Desalination Projects. These agitators ensure the effective mixing of chemicals and slurries, maintaining precise dosing levels and contributing to optimal water quality.

Key Features and Benefits of STEADO Agitators for Water Treatment

Efficient Mixing for Diverse Chemicals

- Tailored for use with a wide range of water treatment chemicals, including Polymer (Poly), Lime, Alum, Sodium Metabisulfite (SMBS), Dolomite, Ferric Chloride (FeCl₃), Antiscalants, Coagulants, and more.

- Precision-engineered impellers ensure homogeneous mixing of both low- and high-viscosity chemicals, preventing sedimentation and enhancing chemical reactions for effective treatment.

Customizable Impeller Designs

- Offer various impeller designs such as Hydrofoil, Pitched Blade, Propellers, and Anchor Types, based on specific tank sizes and chemical characteristics in dosing tanks.

- Each impeller type is designed to ensure maximum mixing efficiency, whether for light slurries or highly viscous mixtures.

Versatile Mounting Options

- Agitators are available with top entry or side entry mounting systems, offering flexibility depending on tank size and layout.

- Adjustable mounting brackets allow for precise positioning, ensuring uniform agitation throughout the entire tank volume.

Corrosion-Resistant Construction

- Built from high-grade stainless steel (SS304/SS316) to withstand harsh chemical environments, including acidic, alkaline, and saline applications.

- Options for specialized materials such as Hastelloy, Alloy, or lined components are available for enhanced corrosion and abrasion resistance in demanding environments.

Variable Speed Control

- Variable-speed drives allow operators to adjust mixing intensity as needed, ensuring efficient and controlled chemical dosing.

- Available in both electric and pneumatic motor configurations, with ATEX-rated options for use in explosive atmospheres.

Energy Efficiency

- Our agitators are designed for energy-efficient operation, reducing power consumption while maintaining optimal performance in the mixing and dosing processes.

Applications in Water Treatment

WTP/WWTP/STP/ETP

- In these systems, STEADO agitators ensure the thorough mixing of dosing chemicals like alum for coagulation, polymers for flocculation, and lime for pH adjustment.

- Effective mixing is critical in sludge treatment applications, where polymers or coagulants are added to facilitate dewatering and settling.

Desalination

- STEADO agitators play a crucial role in the dosing of antiscalants to prevent scale formation in reverse osmosis membranes.

- Also essential in pre-treatment processes, our agitators help in removing suspended particles before desalination.

Sludge Sumps

- Agitators are designed to handle thick, viscous sludges that accumulate in sumps, ensuring the sludge remains fluid for further treatment or dewatering.

Anoxic and Aerobic Mixing

- Agitators are employed in anoxic and aerobic tanks to ensure uniform oxygen distribution and prevent settling, vital for biological processes in wastewater treatment.

Advantages of STEADO Engineering Agitators

Increased Efficiency

- With superior mixing technology, our agitators enhance the chemical reactions and overall efficiency of the water treatment process, ensuring that dosing chemicals are effectively utilized.

Reduced Downtime

- Designed for long-lasting, reliable performance with minimal maintenance, our agitators reduce plant downtime and operational disruptions.

Improved Chemical Utilization

- Proper mixing ensures even distribution of chemicals, minimizing wastage and improving the overall efficiency of the dosing process.

Operational Flexibility

- With variable speed control and customizable designs, our agitators meet the unique demands of different water treatment facilities, from small plants to large-scale operations.

Technical Specifications & Capabilities

Specification

Details

0.5 HP to 25 HP, based on tank volume and viscosity

Variable speed control from 0 to 1500 RPM

Customizable from 500 mm to 8000 mm

200 mm to 4500 mm, based on application

Hydrofoil, Pitched Blade, Propeller, Anchor

SS304, SS316, Alloy 926, Hastelloy, with optional lining (FRP, Rubber, PP, HDPE, PVDF, PFA, PTFE)

Top entry, adjustable brackets

Single-phase and three-phase

230V for single-phase, 415V for three-phase

High-quality seals for chemical and fluid containment

ATEX-rated options available for explosive atmospheres

Poly, Lime, Alum, SMBS, Antiscalants, Coagulants, Anoxic Tanks, Sludge Treatment

Why Choose STEADO Engineering Agitators for Water Treatment Dosing Tanks?

At STEADO Engineering, we understand the critical role that agitators play in the efficient operation of water treatment processes. Whether in WTP, WWTP, STP, ETP, or desalination applications, our agitators ensure reliable and consistent mixing of dosing chemicals, leading to enhanced plant performance and reduced operational costs. With customizable designs, energy-efficient solutions, and superior material construction, STEADO delivers agitators that meet the rigorous demands of modern water treatment facilities.

For more information or to request a custom solution for your water treatment plant, contact STEADO Engineering Private Limited today. Let us help you optimize your water treatment process with our advanced mixing technology.

Know More About Mixing Technology

STEADO mixer agitators come in various specifications tailored to meet the unique needs of our customers. All agitators are tested rigorously to ensure defect-free performance, developed using high-quality materials under the guidance of skilled professionals. Our strong track record includes supplying different types of agitators for a wide array of applications.

Ask Our Agitator Design Experts About:

- Tip Speed

- Pumping Capacity

- Detention Time

- ChemScale

- Velocity Gradient

- Torque

- Specific Power

- Material of Construction

Agitator Manufacturing Champions

STEADO takes pride in its advanced manufacturing techniques:

- Accuracy of Machining using Lathe Machine, CNC, and VMC.

- Qualified & Approved Welding Procedures ensuring durability and reliability.

Tests Conducted by STEADO Quality Specialties

We ensure the highest performance and quality through rigorous testing, including:

- Performance Testing

- Run Trial

- Noise & Vibration Monitoring

- RPM Testing

- Current Monitoring

- Dimensional Checks

- Run Out Testing

- Dynamic & Static Balancing

- Chemical & Mechanical Testing

- Ultrasonic Testing (UT)

- Positive Material Identification (PMI)

- Dye Penetrant Testing (DP)

- Penetrant Testing (PT)

Final Assembly

We care deeply about the aesthetics of our products, ensuring not only top performance but also a polished, professional finish.