Get Professional Help

Agitators for Oil / Gas Sector

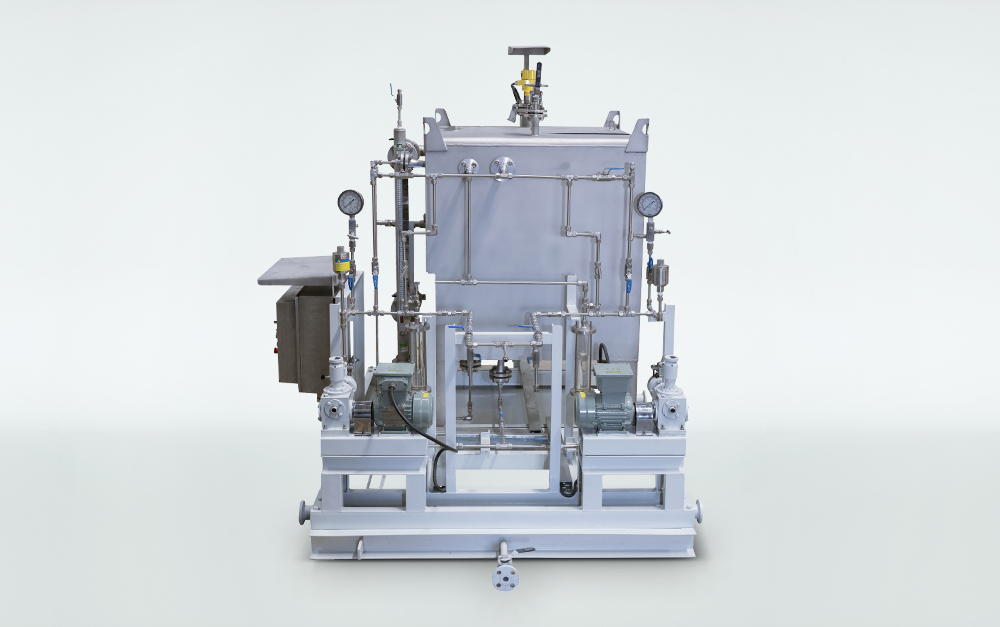

STEADO Engineering offers a comprehensive range of high-performance agitators specifically designed for the Oil and Gas sector, addressing the unique challenges of oil and gas processing applications. Our agitators are engineered to provide efficient and reliable mixing solutions for critical processes such as crude oil refining, chemical dosing, phase separation, and wastewater treatment.

STEADO Agitators for Starch Industry Applications

STEADO offers a range of precision-engineered agitators designed specifically for the starch industry, optimizing processes such as fiber washing, germ separation, and gluten recovery from raw materials like maize, wheat, and potatoes. Our agitators ensure efficient mixing, consistent product quality, and operational energy savings.

Key Features

Tailored Design for Starch Applications

Each agitator is custom-built to match the unique geometry and processing demands of individual tanks, ensuring optimal mixing and homogenization at every stage.

Variable speed drives enable precise control of agitation intensity based on viscosity and material behavior during the starch extraction process.

Material of Construction

Constructed using high-quality stainless steel (SS304/SS316), STEADO agitators offer durability, corrosion resistance, and compatibility with food-grade operations.

Optional special surface finishes and internal polishing are available to meet stringent hygiene standards in food processing.

Energy-Efficient Agitation

Hydrofoil impellers are used to promote low-turbulence, high-flow mixing with minimal power consumption—ideal for delicate starch suspensions.

These impellers optimize energy usage while maintaining gentle, uniform flow patterns to protect product integrity.

Process-Specific Configurations

Our agitators feature impeller designs tailored to the demands of each process stage—ensuring efficient slurry homogenization, suspension of solids, and prevention of sedimentation.

They are engineered to eliminate dead zones and maintain stable, consistent mixing throughout the tank, especially in large-capacity operations.

High-Capacity Mixing Capabilities

STEADO agitators support both batch and continuous production systems and are suitable for various tank sizes—from small process vessels to large fermentation and wash tanks.

Optional features include heating or cooling jackets to maintain ideal process temperatures for enzyme reactions and other sensitive stages in starch production.

With STEADO’s advanced agitator technology, starch manufacturers benefit from precision, efficiency, and consistency—backed by years of engineering excellence and proven industry results.

Applications & Process Aspects

Agitator Solutions by STEADO for Starch Processing Stages

-

Fiber Wash Tank

The fiber wash tank plays a vital role in separating fibrous material from the starch slurry. STEADO agitators ensure consistent, gentle mixing that keeps fibers suspended, preventing settling and clogging. Equipped with high-flow, low-shear impellers, our agitators provide uniform flow throughout the tank—delivering effective washing while preserving starch integrity. -

Pinmill Intermediate Tank

Following the milling process, starch slurry enters the pinmill intermediate tank for stabilization. STEADO agitators maintain homogeneous mixing to prevent sedimentation and ensure slurry consistency for the next separation phase. Our agitators offer controlled, gentle agitation that prepares the slurry efficiently for downstream processing. -

Germ Wash Tank

Germ separation requires the mixture to remain well-suspended for optimal efficiency. STEADO employs axial flow impellers that create strong, yet gentle mixing, ensuring germs stay suspended without compromising starch quality. This design improves separation performance, reduces process times, and increases product purity. -

Grinder Tank

The grinder tank is responsible for refining starch slurry. Consistent mixing is crucial to support the grinding process. STEADO agitators feature multi-stage mixing components that promote continuous suspension, preventing lump formation and ensuring uniform particle distribution. -

Light Gluten Tank

In the light gluten tank, separating gluten from starch requires controlled, laminar flow. STEADO agitators use low-shear impellers that minimize product damage while keeping both gluten and starch in suspension. This results in higher recovery efficiency and maintains the quality of both components.

STEADO’s application-specific agitators are engineered to enhance every stage of the starch production process—from separation and homogenization to product refinement and recovery—ensuring process reliability, consistency, and energy efficiency.

Benefits of STEADO Agitators for Starch Processing

-

Optimal Process Control

STEADO agitators are engineered to offer precise mixing control, ensuring accuracy and efficiency across all stages of starch processing—from fiber washing to gluten recovery. -

Reduced Energy Consumption

Our high-efficiency impellers combined with variable speed drives significantly lower power usage without compromising mixing performance, resulting in reduced operational costs. -

Consistent Product Quality

By enabling uniform slurry mixing, STEADO agitators ensure that starch, fiber, germ, and gluten are processed evenly—delivering consistent and high-quality output. -

Durability & Hygiene

Constructed from food-grade stainless steel (SS304/SS316), our agitators are built for long-term performance and compliance with stringent hygiene standards essential for the starch industry.

Why Choose STEADO Engineering?

At STEADO Engineering, we recognize the vital role agitation plays in the starch production process. Our custom-engineered agitators are designed for every critical stage—fiber washing, germ separation, gluten recovery—ensuring:

Improved productivity

Lower energy consumption

Superior product quality

Reliable and efficient operations

Contact us today to discover how STEADO’s advanced agitation technology can elevate your starch processing performance.

Explore Advanced Mixing Technology

Our mixer agitators are available in multiple configurations tailored to customer needs. Each unit undergoes rigorous in-house testing to ensure flawless performance before delivery.

We focus on:

- Top-tier material quality

- Skilled workmanship

- Design precision

- Process-specific adaptability

Consult Our Agitator Design Experts

When precision matters, trust the data. Our engineering team factors in:

- Tip Speed

- Pumping Capacity

- Detention Time

- ChemScale

- Velocity Gradient

- Torque

- Specific Power

- Material of Construction

Agitator Manufacturing Champions

At STEADO, manufacturing excellence is our benchmark. We ensure:

Precision Machining

- CNC / VMC / Lathe operations

- Tight tolerances & alignment accuracy

Welding Standards

- Qualified welding procedures

- Quality-approved joints for durability

Quality Testing by STEADO Specialists

Every agitator is tested for:

- Performance

- Trial Run

- Noise & Vibration

- RPM & Current

- Dimensional Accuracy

- Run-Out Checks

- DFT (Dry Film Thickness)

- Dynamic & Static Balancing

- Chemical & Mechanical Testing

- UT / PMI / DP / PT Tests

Final Assembly & Finish

We pay attention to what others overlook—the aesthetics of our products. STEADO agitators are not only high-performing but also finished with visual finesse, reflecting the quality of engineering within.